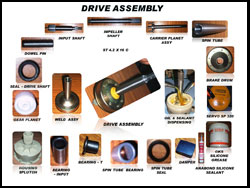

PDM Division was established in the year 2008 with the aim of Manufacturing of Engineering Components and to improve the Business in Global level market. Our motto is to get worldwide recognition by serving Quality products through effective implementation of Quality Management System. We work as a team to enhance our productivity based on the Quality requirement of valued customers. Hence our growth always depends on the entire satisfaction of all customers.

The total Buildup area 850Sqft.

Right from the processing stage, quality consciousness is in build with every employee.