✫ 9000 Sq.ft of Builtup area for critical product assembly in inhouse

✫ Facilitated with proven special process for each and every sequence of process to ensure the quality of the product as per the customer requirement.

✫ The RM to Convesion and Child part to Assembly level sequences ensures the defect free product to end customer.

✫ Migrated from Tally to Sage 300 for systematic data capturing in ERP from Incoming to Sales. Live one point monitoring of RM movement of each sequence.

✫ Live effective and efficiency of production level monitoring in assembly line.

✫ Final inspection bar coding of real spec capturing into print for end customer.

✫ Our Techincal Strength is our Core Team and accomplished “ Zero PPM” in Dump Valve Project for consecutive three years and < 50 PPM in Drive Assembly for consecutive two years.

KMD Unit II Facilities

Facilities

Shop Floor

Quality

Fa Drive Aseembly

Dump Valve

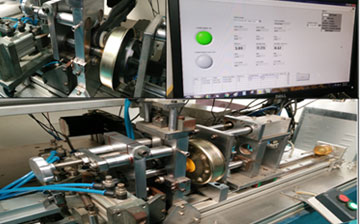

Gear Drive Reliability Room

Gear Drive Reliability Room

End Play & Run Out Inspection SPM

Marposs Knurling Instrument