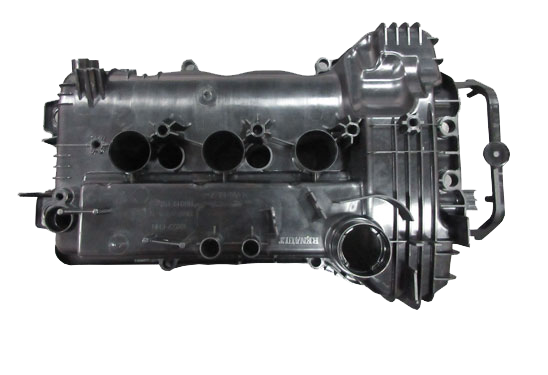

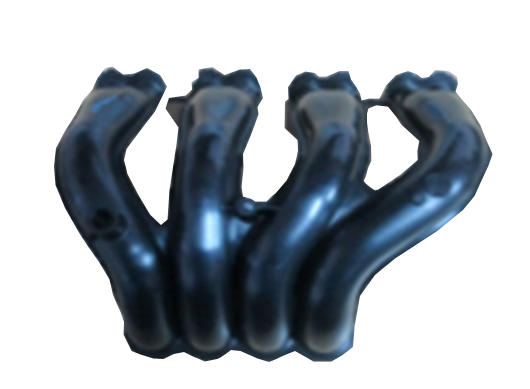

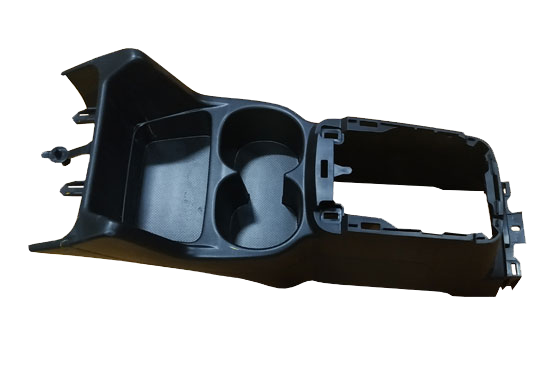

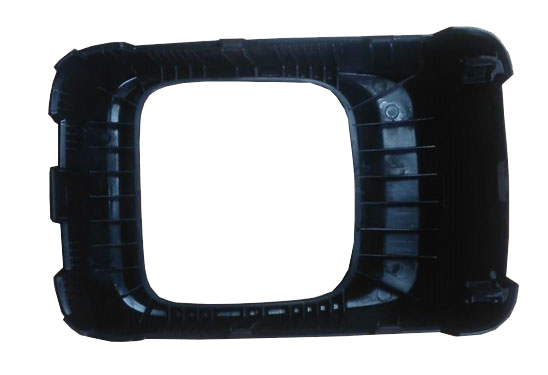

Karthigeya an ISO 9001:2015 Certified group is one among the promising industry in the Plastic Injection Mould, Overhead Cranes and Product Assembly Manufacturer. It caters with a strong presence in segments of automobile, Electrical and Electronic, Engineering products and Home appliances.

Complementing production infrastructure karthigeya functions independently on mould developing segment and processing segment. In recent years, Karthigeya has evolved as a more dynamic, knowledge driven organisation focused towards creation of TOTAL SOLUTION PROVIDER.